|

By Donald H. Harrison

CARLSBAD, Calif.— Home in the Bronx after World War II and studying chemistry

at college, Gerry Greber decided to find the answer to the question that has

perplexed lovers of Jewish cooking for generations. His mother didn't measure

her ingredients, she pinched them, or sprinkled them, or scooped them, and, of

course, whatever meal she was preparing always came out perfect. But how could

this be translated into a workable recipe?

So Greber brought scales and tubes to his mother's kitchen, and observed as she

made another luscious dinner. But, on this occasion, whenever she started

to add an ingredient to the mix, he stopped her in midair and had her put the

ingredients first into one of his devices. He wrote in a little notebook

the exact number of grams or the precise volume of each ingredient. That

evening, Mama's dinner was delicious, so Greber was satisfied that there in his

very own notebook was the elusive secret of Jewish cooking—or, at least, of

his mother's kashe varnishkes. Of course, there remained one final

test. Using the recipe he had so carefully constructed, he needed to

reproduce his mother's cooking.

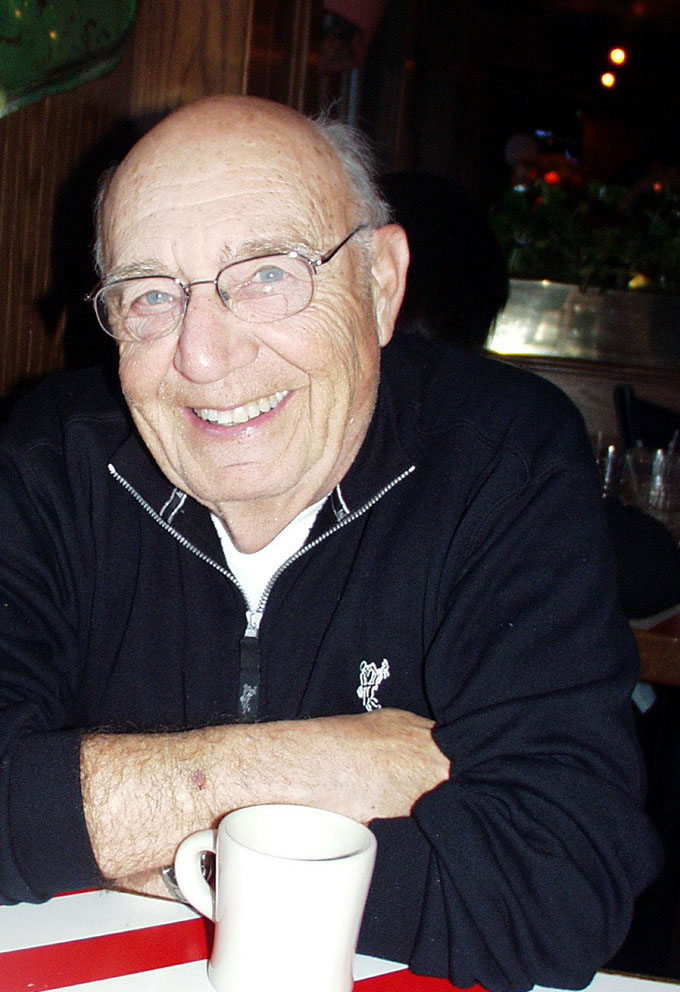

Greber,

78, laughed as he remembered the story that had occurred more than a half

century ago. "And then?" asked I, leaning forward in

anticipation over coffee at a restaurant in his retirement city of Carlsbad.

"Horrible!" he responded. "It tasted horrible." Our

waitress, walking by, looked startled, but soon realized we were talking about

something that had happened long ago. Greber's story illustrates the maxim that

neither the secret of a Jewish mother's cooking, nor of her wisdom, can be set

down in simple writing. (Please see Greber's companion

story for further proof.) Greber,

78, laughed as he remembered the story that had occurred more than a half

century ago. "And then?" asked I, leaning forward in

anticipation over coffee at a restaurant in his retirement city of Carlsbad.

"Horrible!" he responded. "It tasted horrible." Our

waitress, walking by, looked startled, but soon realized we were talking about

something that had happened long ago. Greber's story illustrates the maxim that

neither the secret of a Jewish mother's cooking, nor of her wisdom, can be set

down in simple writing. (Please see Greber's companion

story for further proof.)

He didn't know it then, but that incident was the beginning of Greber's career

in the food industry. He went on to complete a bachelor's degree in

chemistry at CCNY and postgraduate work at Columbia University. He worked

in Washington D.C. at a government laboratory, then moved to Illinois where he

had jobs with Pillsbury, Air-Wick and A.E. Staley over the next decade. At A.E.

Staley.

In 1961, he went to General Foods which had a line of soap products including

S.O.S. cleaning pads—a competitor to Brillo. Greber set to work making a new

product, a combination detergent and fabric softener. The idea was

that people washing their clothes should be able to simply put the product into

the washing machine, at one time, instead of having to first put in the

detergent, then return to the washing machine to add the fabric softener during

the rinse cycle.

Greber developed a formula that worked right in the laboratory. The next

step was to produce it in a commercial quantity. Barely had the lid been

placed on the 25th drum of the product when General Foods sold the S.O.S.

division of its business to Brillo, ending the competition. The decision

was made to abandon the combination fabric softener-detergent product, and

Greber was told to simply keep it, or dispose of it, whichever he

preferred. He brought the drums home to his wife Marilyn and they didn't

have to buy laundry detergents again for more than five years.

With no more soaps to make, Greber was assigned as a product development manager

in General Foods' Kool-Aid Division, named after one of General Foods'

most successful brands. One of the first products that Greber helped to develop

was Open Pit Barbecue Sauce.

"Barbecue sauce is a blend of tomato paste and certain

seasonings," he said. "And we just worked these blends day and

night, finding different levels of tomato paste and seasonings." Once they

produced a product in the laboratory that the research team thought tasted

pretty good, they asked people in the factory to taste it. If the factory

workers (who developed pretty discerning tastes) thought the product was good,

the next step was a "home test," in which consumers would be asked to

rate the product against that of the market leader.

Greber and the others in the laboratory hoped at-home consumers would prefer

their product by a wide margin, but a tie, or even a near tie, such as 52

percent to 48 percent in favor of the market leader, was sufficient to tell the

laboratory it was on the right track.

"Once you get that formula up, then you market it, and then the second part

of the project begins," Greber said. "How do we make it more

profitable ? Now we have a target to shoot for. We try to make the

same product at a lower cost, and that is the big name of the game. By

reducing the costs it becomes really profitable."

Reducing costs means substituting ingredients or changing the proportions of

those ingredients in the hope that the product will taste the same or even

better, so it can be called "new and improved." Another product under

Greber's supervision at that time was Good Seasons Salad Dressing. The

difference between a good salad dressing and a bad one was how spices were

blended.

General Foods would purchase spices from various "flavor houses," that

specialized in accumulating them, then would test them in various blends, trying

to come up with dressings that could survive the taste gauntlet of laboratory

technicians, factory workers and household consumers. Based on the cost of each

ingredient, company accountants would determine whether this or that mixture

would permit the product to be competitively priced. The laboratory team

could be creative, just so long as they brought the product in under the current

price.

Sometimes the tests were successful. Sometimes they ended up like young

Greber's attempt to duplicate Mama's cooking. But the testing went on, day

after day, year after year.

Meanwhile, the marketing division of General Foods conducted focus groups with

consumers. Consumers who typically were housewives were asked what kind of

products would they like One group of women told the marketers how much

they hated to make fried chicken. Dip the chicken in the egg, dunk it in

the flour, fry it in the oil, clean up the whole mess! Wasn't there anyway

to simplify the process?

So the marketers put the question to Greber and his food chemists, and for a

year, they experimented, and tested, and tested and experimented, and then they

brought out their product: Shake 'n Bake. The eggs, the flour, the

seasonings, the cooking oil taste from hydrogenated fats, all were pre-mixed.

All anyone needed to do was drop the chicken into the bag, and then put the

coated chicken into the oven, and it would taste similar to fried chicken—but

without the mess.

Once the product was developed, the testing continued. Less of this spice,

more of that one. New flavors were added to appeal to different

tastes.

Besides Shake 'n Bake product lines of

chicken, there were also Shake 'n Bake product lines of fish and pork

Although he supervised development of the latter product, Greber said he

never tasted it—nor did he have to. Like all the other food

products, the Shake n' Bake pork went through the process of taste tests (by

other people) in the laboratory, factory and at home. Everything was done

by the numbers.

About the same time, General Foods was also working on the idea of cooking the

dinner right in the bag. Another company developed the bag, but Greber's

laboratory was working on the ingredients in which to cook the meat. One

day during a test of this product, a door blew off an oven in the laboratory's

test oven!

Greber's team conducted various tests to

determine what went wrong, learning that as the result of a process known as

super-heating, the bag had exploded. The way to prevent a recurrence of such an

explosion, they learned, was to make sure that there was sufficient flour in the

bag before it was placed into the oven. General Foods thanked Greber for

his analysis, then decided to abandon the product line, fearing a consumer could

be hurt at home using the product. Today, said Greber, other companies do

market cooking bags, but if you read the instructions, you'll see it is

important to put flour inside the bag to prevent "bursting."

In a 25-year career with General Foods, before his retirement in 1986, Greber

worked on numerous products familiar to anyone who has a pantry, or has shopped

in a grocery store. He even worked in General Food's pet foods division,

which manufactured for dogs wrapped meat mixtures that retained their

moistness, as well as various kinds of dry dog foods.

You probably can intuit how they tested the products for the dogs.

Carefully measured amounts of food would be placed in two bowls. In one

would go the product of the market leader; in the other the product under

development. The dogs would eat what they wanted, sometimes preferring one

brand over the other, sometimes seeming to like the brands equally.

Whatever was left over in their bowls was again measured. Whichever bowl

had less food was judged the winner. If the product under development

proved competitive, that is in the 52-48 percent range, it went on to Phase Two

testing.

I asked Greber what dogs really like in their food.

"Fat!" he responded. No matter how many times the food laboratory

produced low-fat dog food, or healthy dog foods, the dogs would overwhelmingly

prefer those with fat. Dog food without fat is like, well, chopped

liver without shmaltz. It can be eaten, but who wants to?

Whatever dog food product General Foods manufactured had

two important requirements in addition to price. First, said Greber, they

had to meet the nutritional requirements of a dog's daily diet. And,

second, said Greber, lowering his voice, they had to be fit for human

consumption. The sad fact of the matter was, he said, that in some poorer

neighborhoods around the country, people were intentionally purchasing dog food

for themselves, so desperate was their poverty.

Two other important aspects of Greber's food career were the testing of new

technology for the food product business and serving as liaison to the mashgiach

for those products which would bear the kosher symbol.

Greber helped introduce extruders to the General Foods manufacturing line.

These devices, obtained from Germany, could shape the food while cooking

it.

Kosher products were made in vats that would be cleaned with boiling water over

two days before the food was added, he said. How did that job get added to

his portfolio? "I was the only Jew around at the

time!"

|